Challenge

Whiskey production consists of mashing, fermenting and distilling. Rum and brandy production do not need mashing, but still need fermentation and distillation capacity. Making your own alcohol is a multi-step process and in multi-step processes, there is always a bottle-neck. Guess what the bottle neck is for rum, brandy, and whiskey production? Yes, fermentation.

Where mashing can be done in like 4 hours, and distillation takes a about 8 hours, it is the fermentation part of spirits production that is the slowest. Depending on product and procedure, fermentation can take 3 to 4 days.

The traditional approach in the distilling industry, in order to overcome the fermentation bottle-neck, is to add more fermenters. For instance, 5 or 6 fermenters for each masher or still.

Even though this is the standard way to deal with the fermentation bottle-neck, there are severe draw-backs to this solution. To name a few:

- Expensive: six new fermenters … that’s a lot of money;

- Floor space: six new fermenters … that takes a chunk out of your distillery space;

- Workforce: pumping, cleaning, managing multiple fermenters is more work;

- Versatility: if you grow, do you buy more fermenters or bigger ones?

Since iStill likes to challenge traditional approaches, here is another take on fermentation. I hope it broadens your horizon and helps you design your perfect distillery with more ease.

Solution

Let’s call the solution I propose “Continuous Fermentation”. The thinking is as follows: “If fermentation is the bottle-neck in alcohol production, that’s the one step we want to do continuously”. The question now becomes: “Can we do so while limiting the number of fermenters, thus limiting capital investment, occupation of floor space, the number of staff needed, while simultaneously boosting flexibility?”

That’s a long question, but luckily the answer is short. One. You just need one fermenter. How’s that for disrupting things, right? And more importantly: how would that work?

If fermentation is the bottle-neck and multiple fermenters isn’t the solution, how do we solve the puzzle? Well, if we limit ourselves to just one fermenter, we make it bigger. Imagine that you have an iStill 500 to distill your whiskey, rum, or brandy in. As a fermenter you’d need one 2000 liter version. One 2000 liter version instead of 5 or 6 smaller ones. Do you run an iStill 2000? In that case consider purchasing an iStill Fermenter 5000.

Now, I hear you thinking: “So I have to wait for 3 or 4 days to ferment 5000 liters … and then I need to do 3 runs in my iStill 2000 to process that? Where’s the gain?” Stay with me, and read my proposed change in procedure:

- Ferment 5000 liter;

- Take up to 2000 liter out of your f5000 and put it in your i2000 for distillation;

- Fill-up the fermenter with fresh substrate and water to 5000 liter;

- Do the distillation run in the iStill 2000;

- Next day? Take up to 2000 liter out of your f5000 and put in in your i2000;

- Fill-up the fermenter with fresh substrate and water to 5000 liter;

- Do the distillation run in the iStill 2000;

- Etcetera.

If a full fermentation takes 3 days, what happens, if we take out (around) 1/3rd for distillation, and we fill-up the fermenter again with new substrate and water? Well, the substrate and water will mix with the (already fermented) beer or wine in the f5000. The introduction of new fermentable sugars will kick-off fermentation again, but since you only add 1/3rd of the “normal” amount of sugars in, fermentation will now only take one day!

By adding just one oversized iStill Fermenter to your distillery, you can start continuous fermentation. In the above examples this continuous fermentation cycle helps you perform one iStill 2000 distillation per day. Five days a week, six days per week, or seven days per week. However often you want to.

Need more capacity? An iStill 2000 can do two runs per 24 hours, so maybe add a fermenter? Two f5000’s allow you to basically distill twice a day. No need for 6 fermenters, and certainly no need for 12.

Implementing continuous fermentation for rum and brandy

The substrates for rum and brandy are liquid instead of particle based, like grains, and do not need mashing. If you want to move towards continuous fermentation, just draw-off 1500 to 2000 liters every day, and add more molasses or fruit juice with water to top-up your f5000.

Since yeast is already present, there is no need to add more. Just make sure you mix in the new substrates and water. That’s all. You need a big iStill Fermenter and a (smaller) iStill distillery.

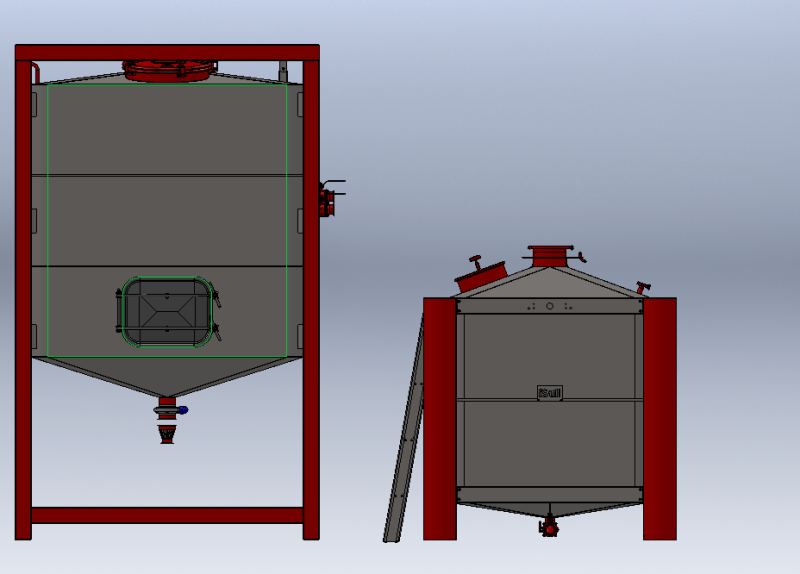

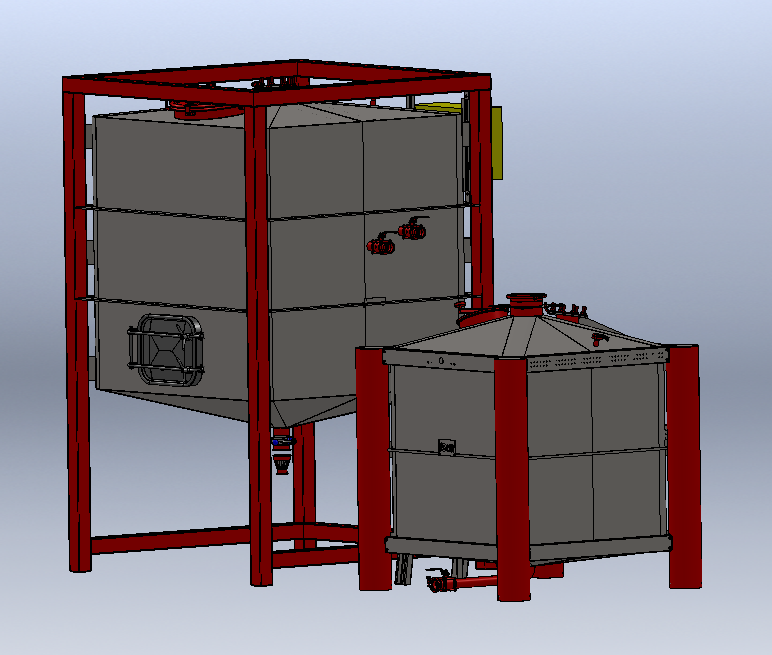

Fermenter 5000 and iStill 2000 for continuous fermentation and distillation …

Implementing continuous fermentation for whiskey

Continuous fermentation for whiskey introduces two minor challenges:

- Grains need mashing in order to convert starches into fermentable sugars;

- Grains are particles and not fluids like molasses or fruit juice.

So in order to to make whiskey on a continuous fermentation basis, you either need to buy an iStill Masher. In the above example the iStill Masher 2000 will do, because that is the amount you need to add every day.

Or you can use the iStill 2000 for mashing. If you use the i2000 for instance for one distillation run per day, you could use it for overnight mashing.

What you don’t want is to leave the spent grain parts in the fermenter. So you either strain the mash and ferment off the grain, or you mix the fermenter before discharging 2000 liters to your iStill 2000, so that as many spent grains are taken out as you add with each new fill-up.

The optional two additional drains allow for very easy filling …

Wouldn’t the yeast mutate after a while?

Nope.

Or, if you want a deeper explanation than “Nope” that still equals nope, settle in for some science. Yeast will definitely mutate over time, but there are a couple things to keep in mind. Mutations only occur during reproduction. Yeast reproduces when it has oxygen and isn’t being horribly stressed. So, most of the 100s of billions of cells in the batch are too stressed to reproduce and are instead trying to stay alive without oxygen by harvesting sugars and converting them to ethanol. When you introduce new batches of wort or molasses water, there’s fresh oxygen, so during that time there’s a chance some yeast will mutate while it reproduces. Now, usually, like 99.999% of the time, that mutation won’t be able to compete with the existing yeast culture. In that case, some yeast mutates, but your flavor doesn’t change and the vast majority of the yeast stay the same. There’s a very, very small chance that that mutation will both out-compete the existing yeast culture and also have detrimental effects on the flavor of your batch. Likewise, any bacteria in the batch are probably too stressed by the high ethanol content and acidity to really mutate in negative ways. On large industrial scales, they’d periodically clear out the tank, do a rigorous cleaning, and start fresh just to be sure. So if you’re worried about mutation or infection, it’s worth cleaning it out and starting over once every 6 months or so. But honestly, you could probably run a setup like this for years without a problem.

So to revive this post, in considering continuous fermentation for the purpose of GNS production which is also grain based (similar to whiskey production), do you think that simply running the agitator will suspend enough of the grain equally that if you siphon off 2000L you will get an equal portion of the grain solids out as well? My concern, is that over time you will end up with either too much grain coming out into your distillation batch (a disproportionate amount), or vice versa, too much grain will stay in the fermenter (building up over time). Has anyone tried this process and proven the concept over time? The idea has many merits, but is it practical for continuous production practices.

If this was made to work, then to achieve clean GNS from on-grain continuous fermentation, one would have to either use a process of hydro-separation and/or filtration to remove excess flavours created by on-grain fermentation/distillation, but it would eliminate the need for lautering to remove grain prior to fermentation. The question then is, which one of those process is easier and less costly over time (labour & materials) : lautering (or other means of grain separation prior to fermentation) or post-distillation processing/filtration.